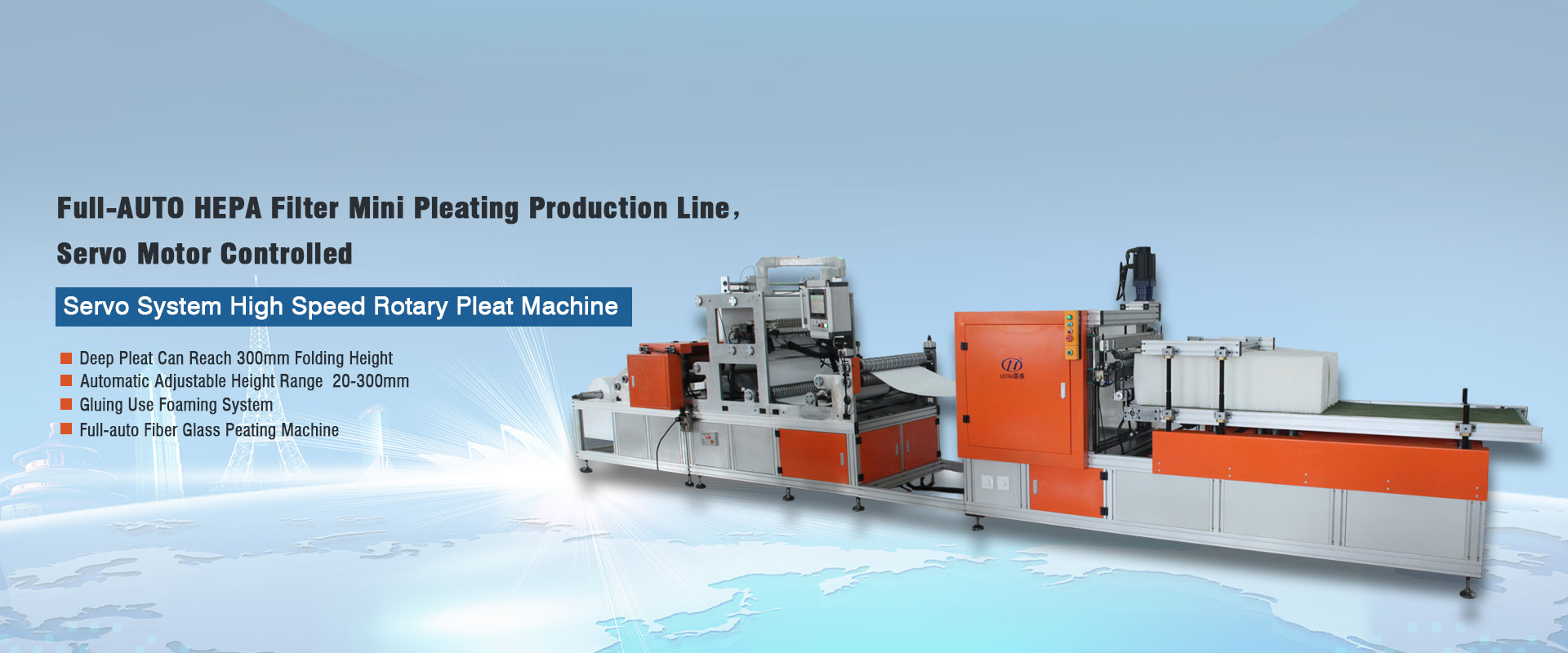

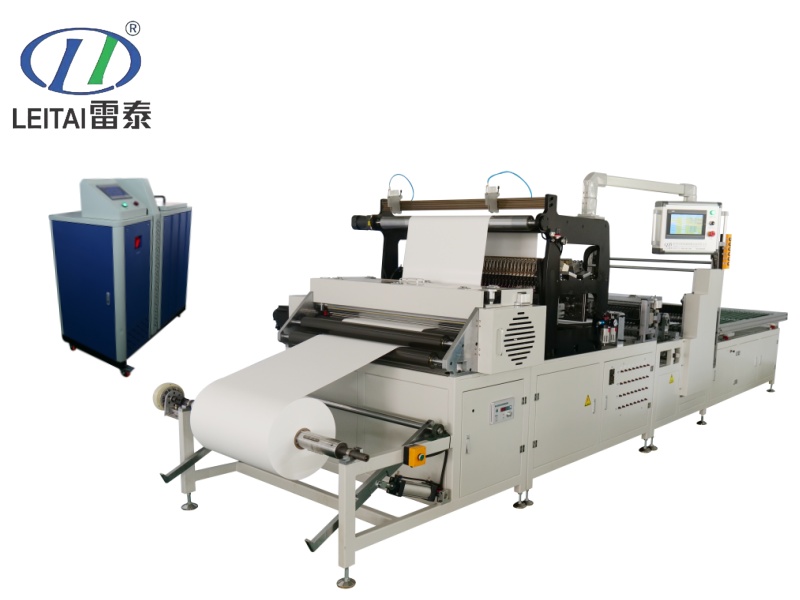

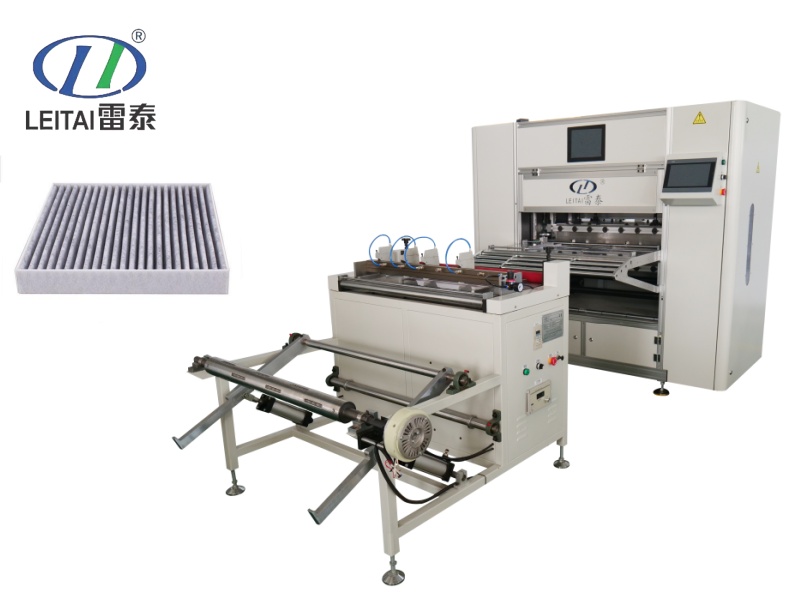

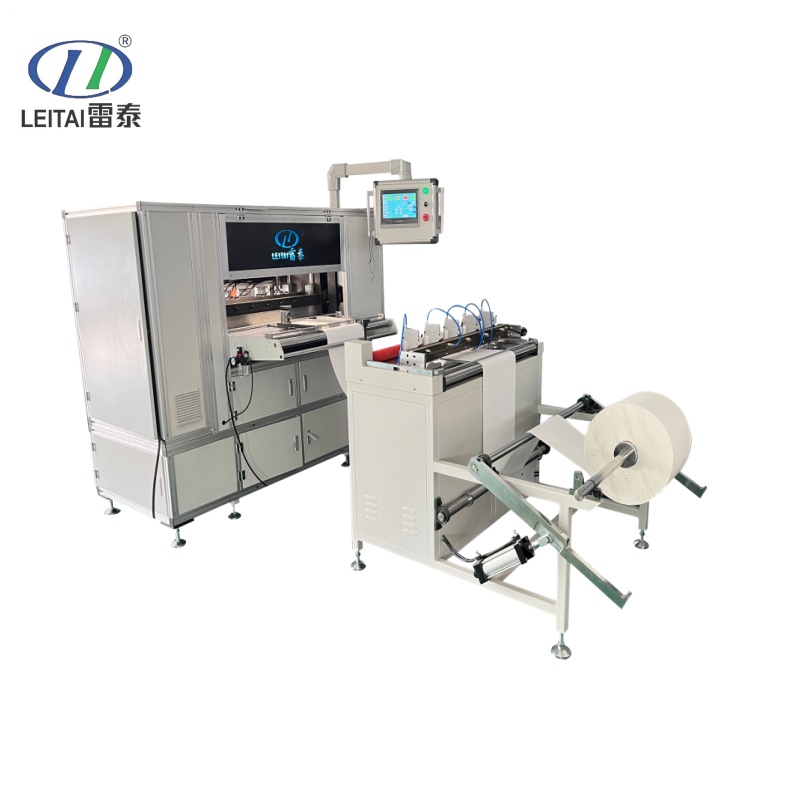

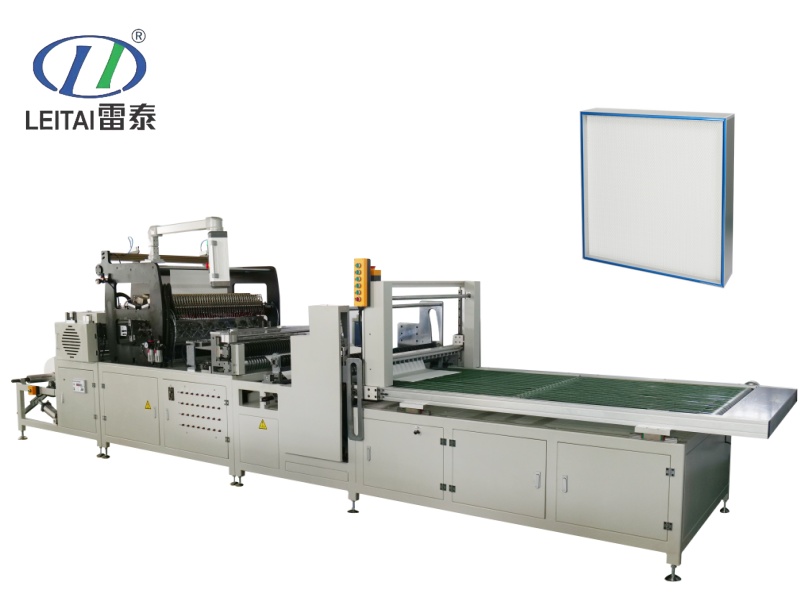

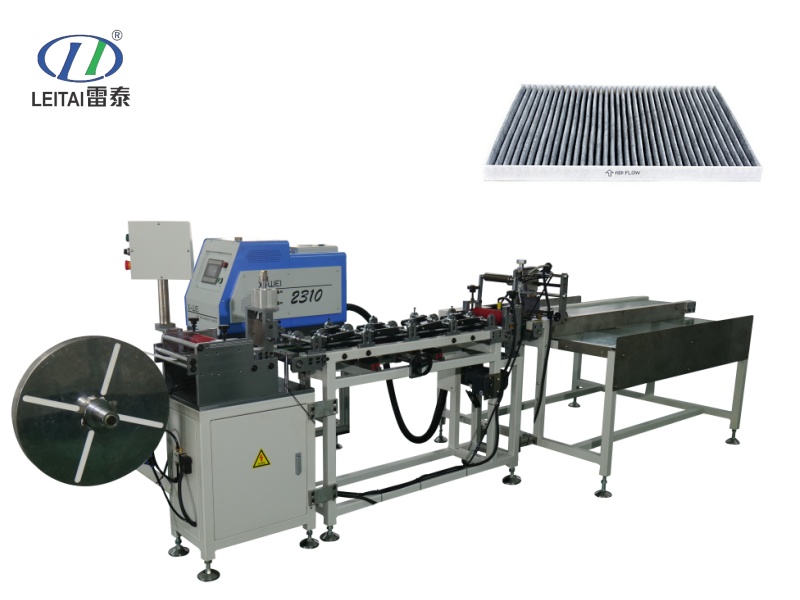

Used for producing fiberglass non-woven air filter media, particularly suitable for folding and gluing high-fold filter cartridges.

Read More

What Are You Looking For?

What Are You Looking For?

Service Hotline:

Service Hotline:

Get Quote

Get Quote

IPv6 Network Supported

IPv6 Network Supported