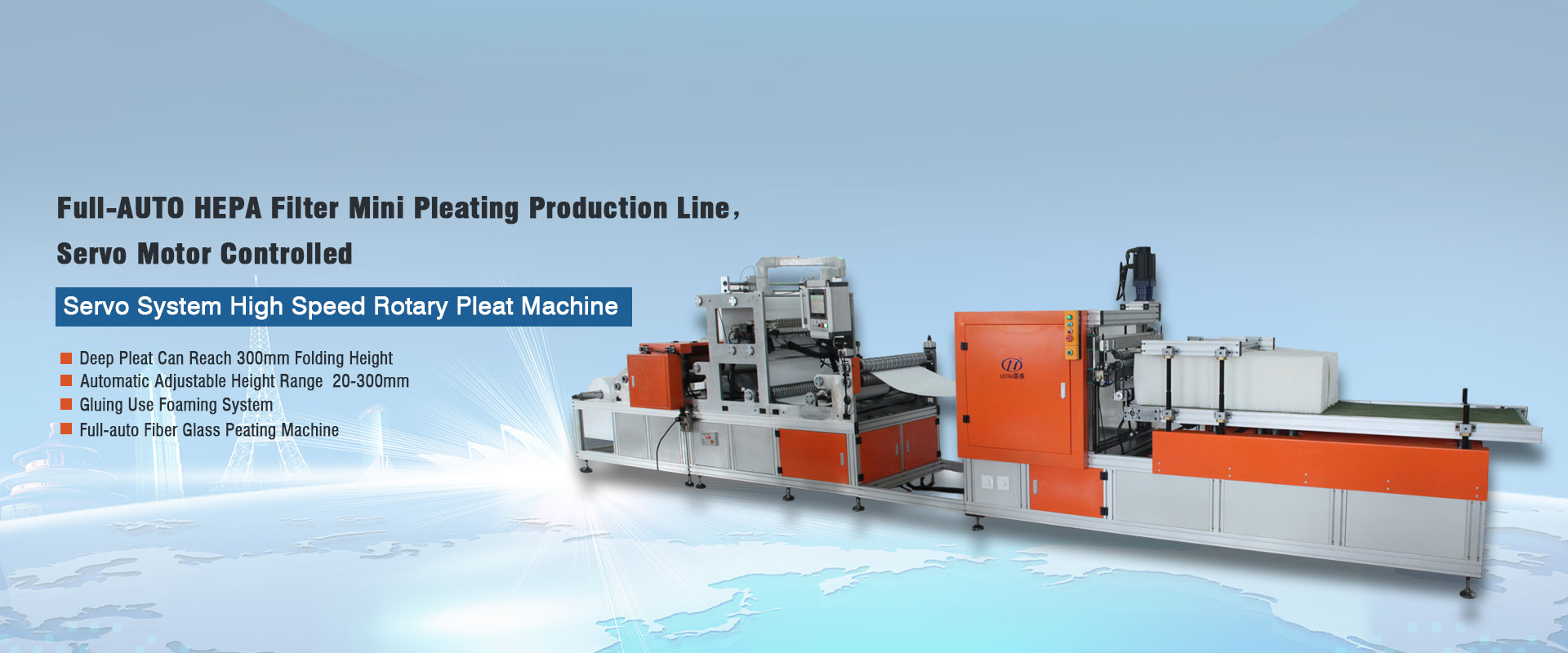

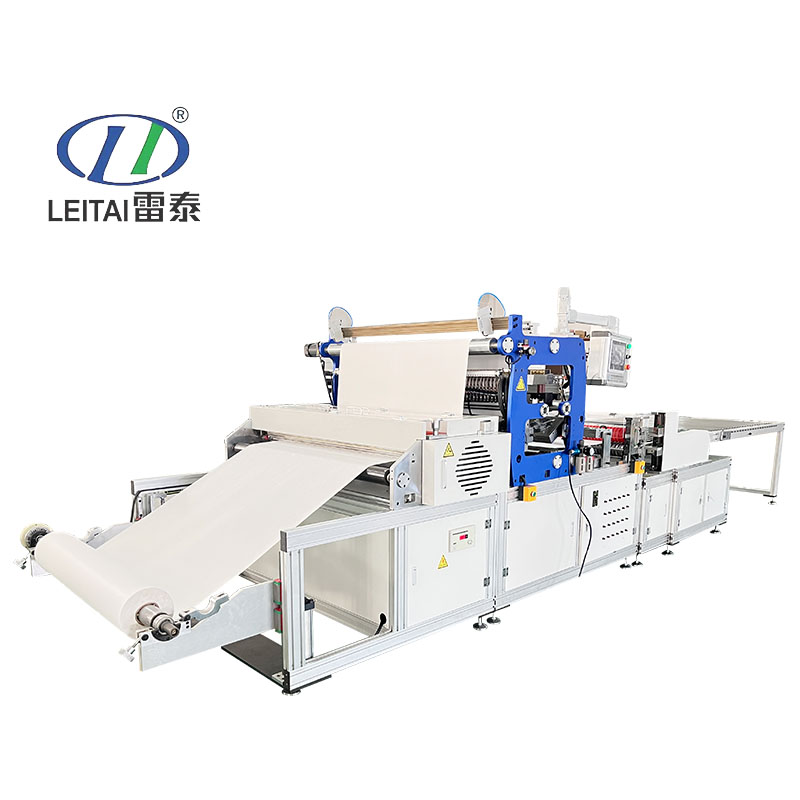

LTWG-300-700II Full auto CNC HEPA filter Pleating Machine Make Up Pleating, Gluing, Conveyor. Operating System Via Touch Screen Interface And It Has Modern Monitoring System. Pleating Height Can Do (20-300mm) Via Pleating Servo Motor. The HEPA Air Filter Of Glass Fiber Material Pleated By This mini pleat production line is Accurate In Size, Flat And Consistent,Thickness Of The Glue Line Is Consistent.

Read More

What Are You Looking For?

What Are You Looking For?

Service Hotline:

Service Hotline:

Get Quote

Get Quote

IPv6 Network Supported

IPv6 Network Supported